Understanding the Importance of 5/8 Redline Gauge Glass for Your Business

In the world of industrial and commercial applications, having the right components can make a monumental difference in the efficiency and safety of operations. One crucial element in many systems is the 5/8 redline gauge glass. This article delves deep into the significance of this essential gauge glass, how it functions, its applications, and the best practices for purchasing and maintaining it.

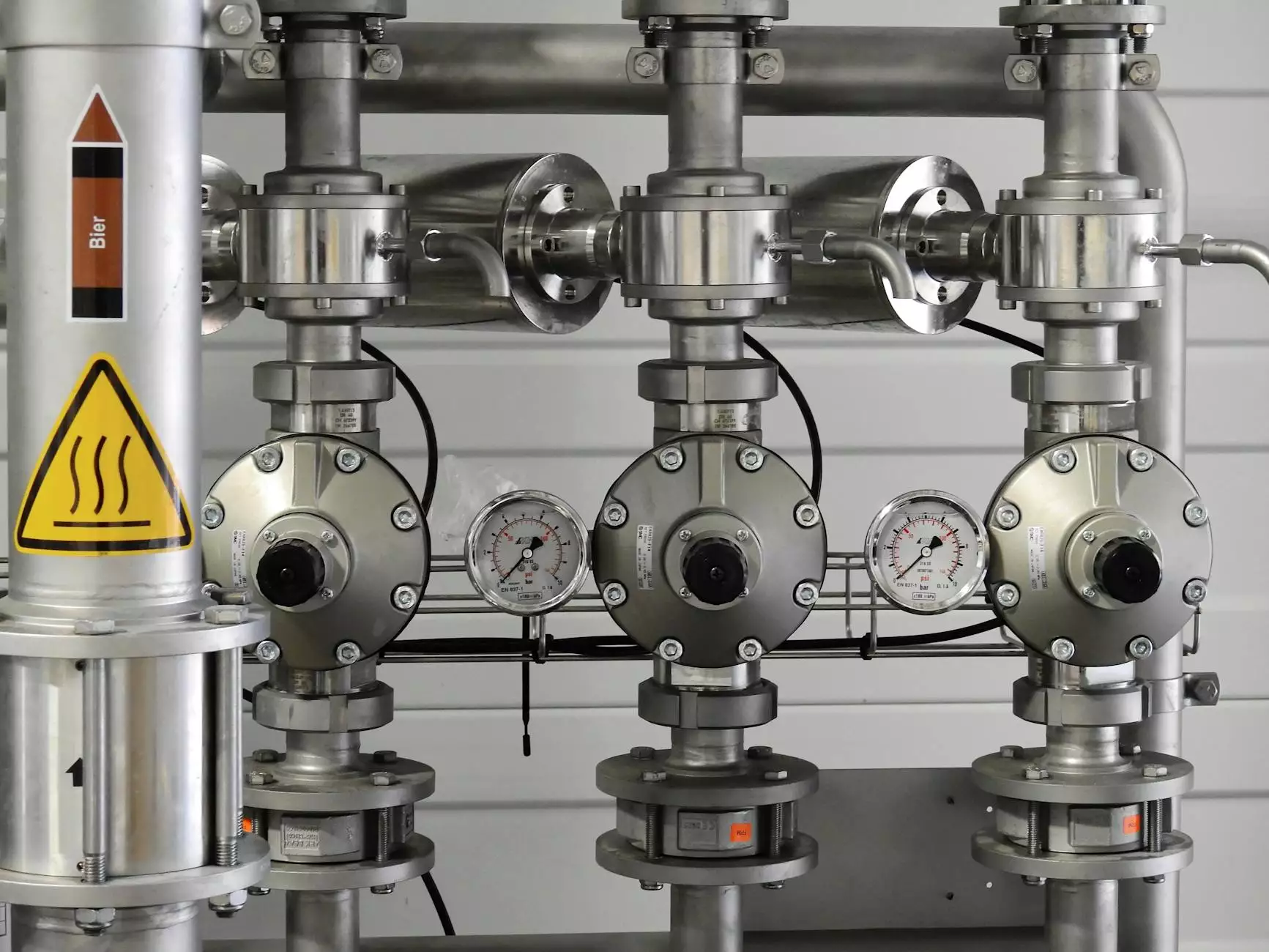

What is Gauge Glass?

Gauge glass, also known as sight glass, is a transparent tube or panel that allows operators to see the level of fluids in tanks, boilers, or other containers. The 5/8 redline gauge glass specifically refers to a gauge glass that has a diameter of 5/8 inches, often marked with a red line to indicate the safe operating level of the fluid.

Why is the 5/8 Redline Gauge Glass Important?

The 5/8 redline gauge glass serves various critical functions across multiple industries. Here are several reasons why it is indispensable:

- Visual Monitoring: It provides a clear visual indication of fluid levels, ensuring operational safety and efficiency.

- Durability: Made from robust materials, gauge glass can withstand high pressures and temperatures, essential for industrial applications.

- Safety Measures: The redline marking allows operators to quickly identify safe fluid levels, reducing the risk of overfilling or excessive depletion.

- Cost-Effectiveness: By preventing spills and leaks through accurate monitoring, businesses can save significant amounts on material costs and environmental compliance.

Applications of 5/8 Redline Gauge Glass

The applications of 5/8 redline gauge glass span across various sectors. Here are key areas where it is commonly used:

1. Industrial Plants

In industrial plants, gauge glasses are vital for monitoring liquids in tanks and reservoirs. The 5/8 redline gauge glass helps in maintaining optimal fluid levels crucial for production processes.

2. Boilers and Steam Systems

Boilers require precise water levels for efficient operation. The gauge glass provides a visual reference, helping operators prevent boiler failures or dangerous overheating.

3. Chemical Processing

In chemical processing industries, accurate fluid monitoring is critical. The 5/8 redline gauge glass ensures that harmful chemicals are managed safely and effectively.

4. Marine Vessels

Marine applications utilize gauge glass to monitor fuel and water levels. This ensures efficient operations and helps in adhering to safety regulations.

Choosing the Right 5/8 Redline Gauge Glass

Selecting the appropriate 5/8 redline gauge glass can be a daunting task given the variety of options available. Here are essential factors to consider:

Material Type

The material of gauge glass is critical for its durability and resistance to various chemicals. Common materials include:

- Glass: Ideal for monitoring water and non-corrosive liquids.

- Borosilicate Glass: Suitable for high-temperature applications.

- Plastic: Often used for low-pressure applications.

Size and Configuration

Ensure that the gauge glass fits appropriately into existing fittings. The 5/8 redline gauge glass must align with your operational requirements.

Pressure and Temperature Ratings

Verify the pressure and temperature ratings to ensure safety and reliability. The gauge glass should withstand the specific conditions of your application.

Installation Best Practices for 5/8 Redline Gauge Glass

Proper installation of 5/8 redline gauge glass is critical for its functionality. Here are key installation practices:

- Use Appropriate Seals: Ensure the use of high-quality sealing materials to prevent leaks.

- Follow Manufacturer Guidelines: Adhere to installation guidelines provided by manufacturers for optimal performance.

- Regular Inspection: Conduct regular inspections post-installation to ensure no damage has occurred.

Maintenance Tips for 5/8 Redline Gauge Glass

Maintaining your 5/8 redline gauge glass is crucial for longevity and accuracy. Consider these maintenance tips:

- Clean Regularly: Ensure the glass is cleaned regularly to remove build-up that may obscure visibility.

- Check for Cracks: Inspect the glass for any cracks or defects that could cause leaks.

- Monitor for Wear: Keep an eye on fittings and seals for wear and tear over time.

Where to Buy 5/8 Redline Gauge Glass

When it comes to purchasing high-quality 5/8 redline gauge glass, you have plenty of options. It is essential to choose a reputable supplier. A great resource is gage-glass.com, which offers a wide range of gauge glasses suitable for various applications. Here’s what to look for when choosing a supplier:

- Product Variety: Ensure they have a diverse selection of gauge glasses.

- Quality Assurance: Look for suppliers who guarantee product quality and compliance with industry standards.

- Customer Support: Opt for businesses that provide excellent customer service and support for your queries.

Conclusion

In conclusion, the 5/8 redline gauge glass is a vital component that enhances operational safety, efficiency, and monitoring in numerous applications. Understanding its significance, applications, installation best practices, and maintenance tips can significantly impact your business’s success. When looking to purchase, consider trusted suppliers like gage-glass.com for quality products that cater to your needs.

By prioritizing the right gauge glass, businesses can not only ensure safety and compliance but also enhance productivity and overall operational effectiveness.