Unleashing Excellence in Metal Fabrication: The Ultimate Guide to CNC Lathing Parts by DeepMould

In the constantly evolving landscape of industrial manufacturing, metal fabrication stands as a foundational pillar supporting diverse sectors such as aerospace, automotive, electronics, medical devices, and heavy machinery. Among the many specialized techniques, the creation of cnc lathing parts has emerged as a critical process, enabling the production of complex, precise, and high-performance metal components. DeepMould, a leader in metal fabricators, excels in delivering innovative solutions tailored to meet the rigorous demands of modern industry. In this comprehensive guide, we delve deep into the world of cnc lathing parts, showcasing how DeepMould elevates manufacturing standards through unmatched craftsmanship, advanced technology, and customer-centric approaches.

Understanding the Significance of CNC Lathing in Metal Fabrication

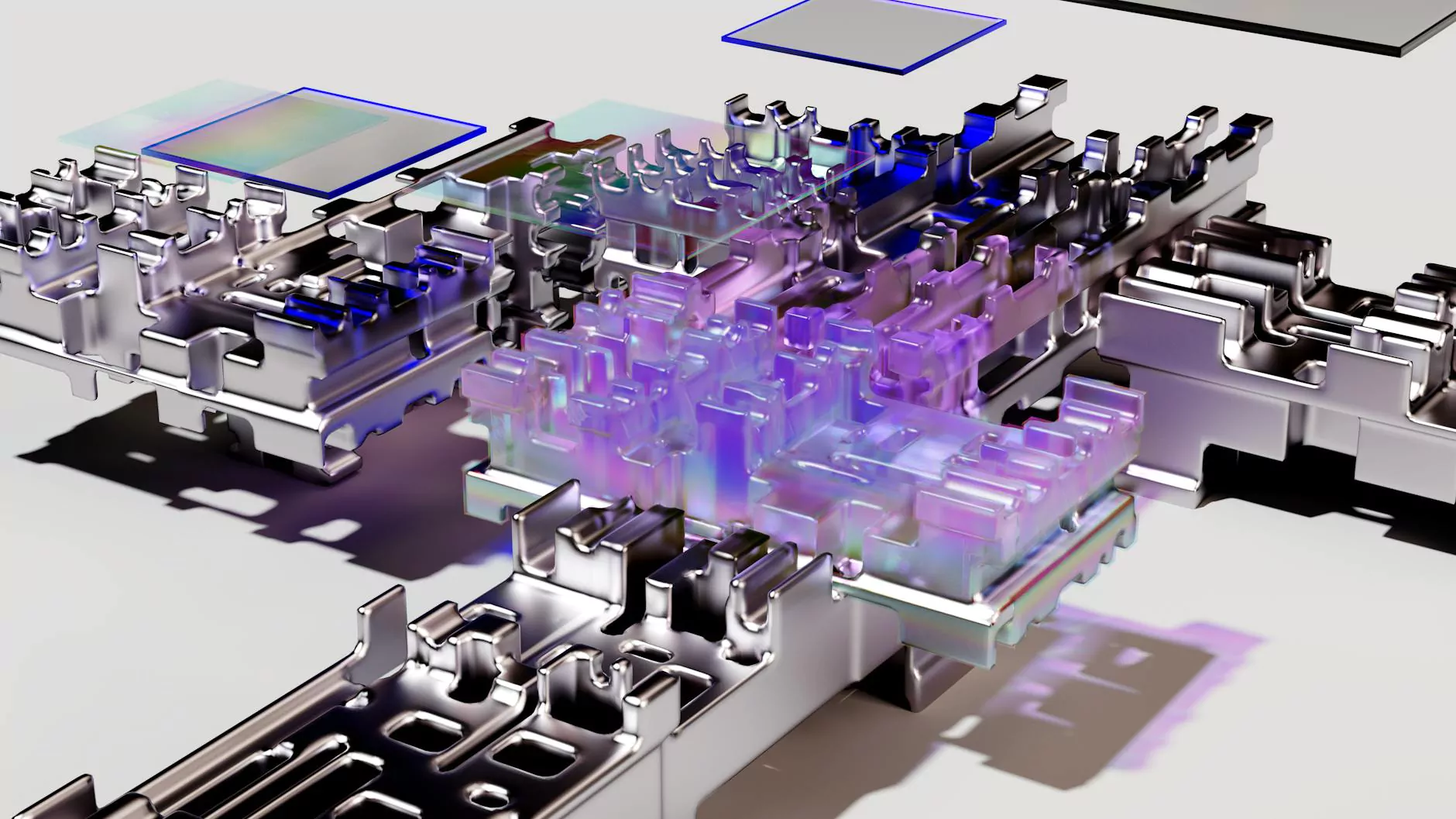

At the heart of modern metal fabrication lies the Computer Numerical Control (CNC) lathing process, a precise and efficient method that transforms raw metal stock into complex, detailed components. The term cnc lathing parts encompasses a wide array of products, from simple cylindrical pieces to intricate geometries with tight tolerances. These parts are integral to automotive engines, aerospace components, industrial machinery, and consumer electronics.

What makes cnc lathing stand out is its ability to produce parts with absolute precision, repeatability, and high complexity—features impossible to achieve with manual machining. The integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems allows for automated, highly controlled operations, reducing human error and boosting productivity.

Why Choose DeepMould for Your CNC Lathing Parts Needs?

DeepMould has established itself as a distinguished metal fabricator specializing in cnc lathing parts. Our commitment to quality, innovation, and customer satisfaction makes us the preferred partner for businesses seeking reliable machining solutions. Here are some compelling reasons to trust DeepMould:

- State-of-the-Art Technology – We invest continuously in the latest CNC lathes and automation tools, ensuring the highest precision and efficiency.

- Expert Workforce – Our team comprises highly skilled engineers and technicians with extensive experience in complex machining processes.

- Customized Solutions – We tailor our manufacturing processes to meet your specific design, material, and performance requirements.

- Comprehensive Quality Control – Our rigorous inspection protocols, including 3D measurement, material testing, and surface finishing, guarantee defect-free cnc lathing parts.

- Rapid Turnaround – We optimize workflows to deliver even large volume orders within tight deadlines without compromising quality.

- Environmental Responsibility – Our manufacturing practices prioritize sustainability and eco-friendliness.

Precision Manufacturing of CNC Lathing Parts: Our Process

The creation of cnc lathing parts at DeepMould involves a meticulous, multi-stage process designed to optimize accuracy, durability, and surface finish. Below, we outline our standard workflow:

1. Design and Prototype Development

Using advanced CAD software, our engineers collaborate with clients to develop detailed 3D models of the desired parts. Prototype manufacturing allows for validation, testing, and adjustments prior to full-scale production.

2. Material Selection and Preparation

We source only high-grade metals such as stainless steel, aluminum, brass, titanium, and specialized alloys. Material choice depends on application requirements including strength, corrosion resistance, heat tolerance, and weight considerations.

3. CNC Programming and Setup

Our technicians generate precise CNC code based on the finalized design. The setup involves mounting the raw material on the lathe machine, calibrating tools, and establishing parameters for spindle speed, feed rate, and cutting paths.

4. Machining and Production

The core of the process involves ##cnc lathing parts## being produced via automated cutting, turning, threading, and drilling. We utilize multi-axis CNC lathes capable of complex geometries, ensuring tight tolerances and exceptional surface finishes.

5. Surface Finishing and Quality Assurance

Post-machining treatments such as polishing, anodizing, or coating enhance performance and aesthetics. Our quality control team performs thorough inspections using coordinate measuring machines (CMM), optical comparators, and other precision tools to verify dimensional accuracy and defect-free surfaces.

Types of CNC Lathing Parts We Specialize In

- Standard Cylindrical Components – Shafts, axles, and pins designed for mechanical assemblies.

- Complex Geometries – Parts with tapered sections, threads, grooves, and intricate features achieved through multi-axis machining.

- Prototyping and Small Batch Production – Quick turnaround for custom designs, ideal for testing and development phases.

- Mass Production – Economical manufacturing of high-volume parts with consistent precision.

- Specialized Alloys – Machining titanium, inconel, and other difficult materials for demanding applications.

Applications of CNC Lathing in Various Industries

Manufacturing cnc lathing parts is vital across numerous sectors. Some key applications include:

- Aerospace: Critical structural elements, engine components, and landing gear parts that require absolute precision and safety standards.

- Automotive: Engine parts, drive shafts, fasteners, and custom prototypes that demand durability and high tolerances.

- Medical Devices: Surgical instruments, implants, and precision components that meet strict biocompatibility and cleanliness standards.

- Electronics: Connectors, housings, and heat sinks with complex geometries and exact dimensions.

- Industrial Machinery: Gear components, bushings, and shafts critical to the performance and longevity of manufacturing equipment.

Key Advantages of Partnering with DeepMould for CNC Lathing Parts

Working with DeepMould elevates your manufacturing capabilities by offering:

Superior Quality and Precision

Our focus on strict quality control ensures each cnc lathing part adheres to the most demanding specifications, minimizing defects and rework.

Customization and Flexibility

No matter how intricate or unique your design, we have the capabilities and experience to bring your concepts to life.

Innovation-Driven Solutions

We continuously upgrade our machinery and adopt the latest manufacturing techniques, such as high-speed machining and multi-axis turn-mill centers, to deliver innovative solutions.

Cost Savings

Efficient manufacturing processes and material optimization reduce waste and production costs, providing you with competitive pricing without sacrificing quality.

Timely Delivery

Our streamlined workflow and logistics ensure your cnc lathing parts reach you on schedule, supporting your project timelines and market demands.

Concluding Thoughts: Why DeepMould Is Your Ultimate Choice for Metal Fabrication

In an industry where precision, quality, and reliability are non-negotiable, DeepMould stands out as a premier metal fabricator specializing in cnc lathing parts. Our cutting-edge technology, experienced team, and unwavering commitment to excellence empower us to deliver products that exceed expectations. Whether you need prototypes, small batches, or mass production, partnering with us guarantees superior results that drive your business forward.

Unlock your manufacturing potential today by choosing DeepMould as your trusted partner for cnc lathing parts. Experience the difference of working with industry leaders dedicated to precision, innovation, and customer satisfaction.