The Ultimate Guide to Diesel Engines with Water Pumps: Power, Efficiency, and Reliability

In the realm of industrial machinery and automotive engineering, diesel engines with water pumps stand out as critical components that drive performance, durability, and efficiency. These sophisticated systems are integral to various applications, ranging from heavy-duty construction equipment to maritime vessels, agricultural machinery, and power generation units. As demand increases for reliable and high-performing diesel engine parts, especially water pumps, understanding their functionality, importance, and sourcing becomes paramount for manufacturers, mechanics, and businesses involved in engine maintenance and procurement.

Understanding the Role of Diesel Engines with Water Pumps

A diesel engine with water pump combines the robust power of a diesel combustion system with an integrated or auxiliary water pump designed to circulate coolant through the engine and other vital components. This synergy ensures that the engine maintains optimal operating temperatures, prevents overheating, and prolongs service life. The diesel engine with water pump is thus a core element in systems where sustained, reliable power is necessary under demanding conditions.

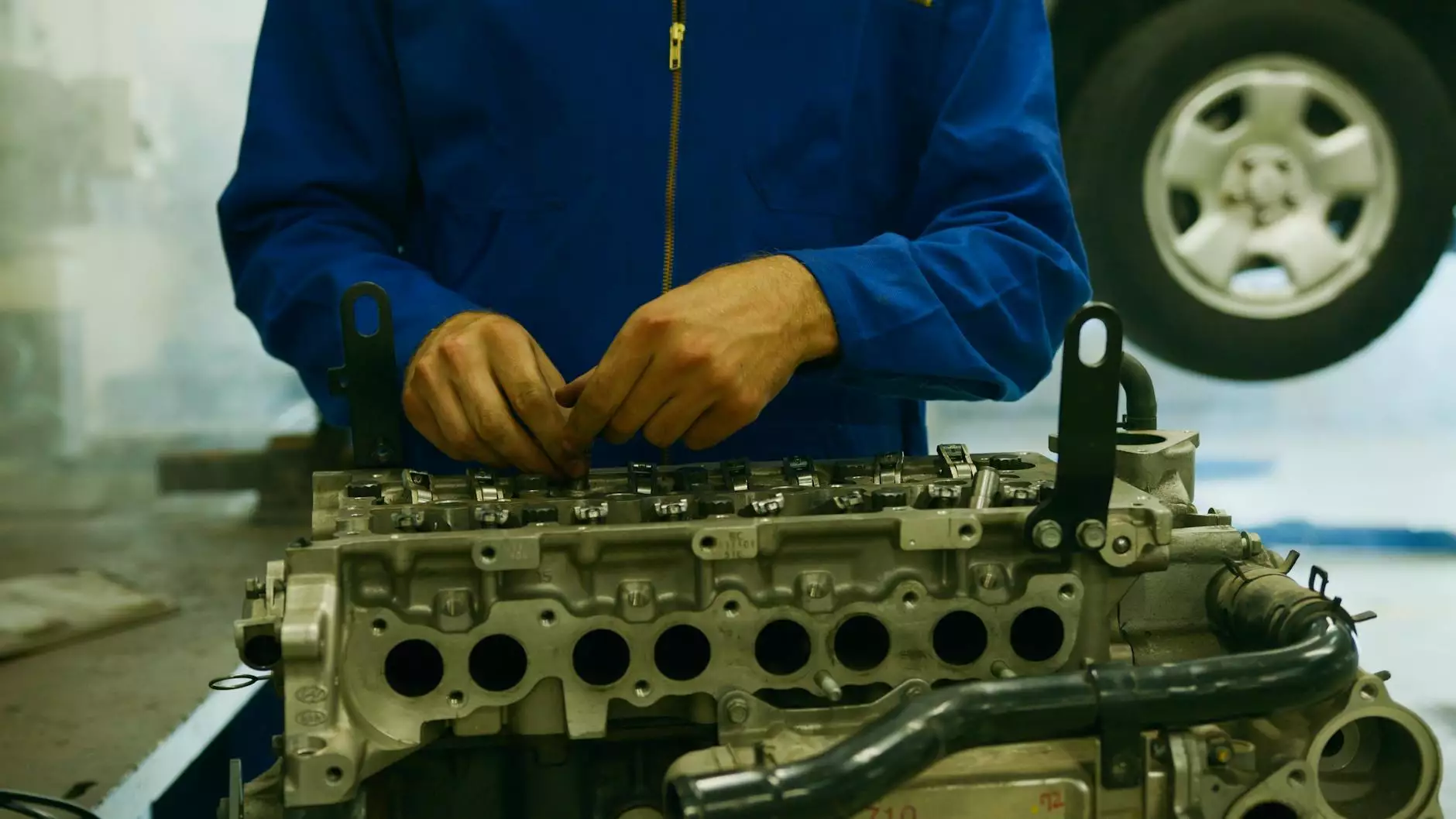

Key Components of a Diesel Engine with Water Pump

Understanding the intricate parts that comprise a diesel engine with water pump is crucial to appreciating its reliability and maintenance needs. The main components include:

- Engine Block: The main structure housing cylinders, pistons, and other critical internal parts.

- Fuel Injection System: Delivers diesel fuel into the combustion chamber under high pressure, ensuring efficient combustion.

- Pistons and Cylinders: Convert fuel energy into mechanical motion, driving the engine’s crankshaft.

- Cooling System with Water Pump: Circulates coolant (water or antifreeze mixture) to manage engine temperature effectively.

- Lubrication System: Keeps internal components properly lubricated, reducing wear and tear.

- Exhaust System: Expels combustion gases, ensuring environmental compliance and efficient operation.

The Importance of Water Pumps in Diesel Engines

The water pump in a diesel engine is more than just a circulatory component; it plays a vital role in safeguarding the engine's integrity. Efficient water pumps ensure the circulation of coolant, which absorbs heat generated during combustion. This process prevents overheating, which can lead to catastrophic engine failure, warped components, or reduced lifespan.

Modern diesel engine with water pump systems are designed for high efficiency and longevity, with some water pumps featuring variable speed drive capabilities, corrosion-resistant materials, and serpentine belt or gear-driven mechanisms for improved durability.

Types of Water Pumps Used in Diesel Engines

There are various water pump configurations tailored to different engine sizes and operational demands:

- Centrifugal Water Pumps: Most common, with impellers that propel coolant outward using rotational force. Suitable for most diesel engines.

- Gear-Driven Water Pumps: Powered directly by the engine’s timing gear, offering reliable performance for heavy-duty applications.

- Electric Water Pumps: Used in advanced systems where engine-driven pumps are supplemented or replaced to optimize efficiency and cooling control.

- V-Belt Driven Pumps: Common in older models, driven by a belt connected to the engine's crankshaft.

Benefits of Using High-Quality Diesel Engine Parts from Client-Diesel.com

When it comes to maintaining or upgrading your diesel engine with water pump, sourcing high-quality spare parts is paramount. Client-Diesel.com has established itself as a leading supplier specializing in diesel engine parts and spare parts, providing several advantages:

- Superior Quality Materials: Ensuring the durability and longevity of parts like water pumps, pistons, and injectors.

- Certification and Compliance: All products meet international standards such as ISO, SAE, and DIN, ensuring safety and quality.

- Wide Range of Parts: From basic components to advanced systems, enabling comprehensive solutions for all engine types.

- Competitive Pricing: Offering affordable yet dependable spare parts to maximize your ROI.

- Expert Support: Providing technical assistance, installation guidance, and maintenance advice to ensure optimal performance.

Advantages of a Diesel Engine with Water Pump in Industry

The integration of a diesel engine with water pump presents multiple advantages across industries:

- Enhanced Efficiency: Continuous cooling ensures that the engine operates at peak performance without thermal disruptions.

- Increased Reliability: High-quality parts minimize breakdowns and reduce maintenance costs over time.

- Versatility: Suitable for stationary and mobile applications, including generators, construction machinery, and marine engines.

- Environmental Compliance: Efficient cooling and combustion systems reduce emissions and environmental footprint.

- Economic Benefits: Improved fuel economy and reduced downtime translate into significant cost savings.

Design Innovations and Future Trends in Diesel Water Pumps

Advancements in technology continue to transform the design and functionality of water pumps in diesel engines. Noteworthy trends include:

- Smart Control Systems: Integration with electronic control units (ECUs) for real-time monitoring and adaptive cooling.

- Corrosion-Resistant Materials: Use of composites and specialty alloys to enhance longevity in harsh environments.

- Energy-Efficient Designs: Variable speed pumps that adjust flow rates based on engine demands, reducing power consumption.

- Modular Pump Assemblies: Easy-to-replace modules facilitate maintenance and reduce downtime.

Maintenance Tips for Diesel Engines with Water Pumps

Proper maintenance is crucial to maximize the lifespan and efficiency of both the diesel engine with water pump. Here are essential tips:

- Regular Inspection: Check for leaks, corrosion, or wear on water pump components.

- Coolant Quality: Ensure the coolant mixture is optimal, free of contaminants, and replaced periodically.

- Lubrication: Maintain proper lubrication of moving parts to prevent premature failure.

- Replace Worn Parts: Use genuine spare parts from trusted suppliers like Client-Diesel to ensure compatibility.

- Monitor Operating Temperatures: Use gauges to detect overheating early and prevent long-term damage.

Conclusion: Investing in Quality for Optimal Performance

As industries continue to rely heavily on diesel-powered machinery, the diesel engine with water pump remains a cornerstone of reliable power generation and mechanical performance. By choosing premium spare parts from reputable suppliers such as client-diesel.com, businesses can ensure their equipment operates efficiently, safely, and with minimal downtime. Embracing technological advancements and adhering to proper maintenance routines will further enhance the lifespan and productivity of your diesel engines.

Whether you're sourcing parts for new equipment or upgrading existing systems, prioritize quality, compatibility, and support services. Your investment in diesel engines with water pumps directly impacts your operational success and sustainability.