Revolutionize Your Business with State-of-the-Art Fabric Label Printers

In today's highly competitive marketplace, businesses must leverage cutting-edge technology to enhance their products, streamline operations, and create distinctive branding. Among the most critical components in product presentation and branding—particularly in the textiles and apparel industries—are high-quality fabric labels. These labels not only serve as vital branding tools but also provide necessary information such as care instructions, material composition, and origin. To produce these labels efficiently, reliably, and with exceptional visual quality, investing in fabric label printers is paramount.

Understanding the Power of fabric label printers: A Key to Business Growth

Fabric label printers are specialized printing machines designed to print directly onto fabrics with precision and durability. These advanced printers cater to a broad spectrum of industries including fashion, sportswear, corporate apparel, and home textiles. The ability to efficiently produce custom, high-resolution labels significantly impacts brand perception, customer satisfaction, and operational efficiency.

How Fabric Label Printers Transform Your Business Operations

Adoption of fabric label printers results in:

- Cost efficiency: Reduce outsourcing costs by printing labels in-house with high speed and accuracy.

- Flexibility: Rapidly produce small or large batches, custom designs, and seasonal variations without delay.

- Enhanced branding: Create vibrant, detailed labels that reinforce brand identity.

- Durability: Produce labels that withstand washing, wear, and environmental factors, ensuring long-lasting brand presence.

- Streamlined workflow: Integrate seamlessly into your manufacturing process to improve productivity and reduce lead times.

Key Technologies Behind Fabric Label Printing

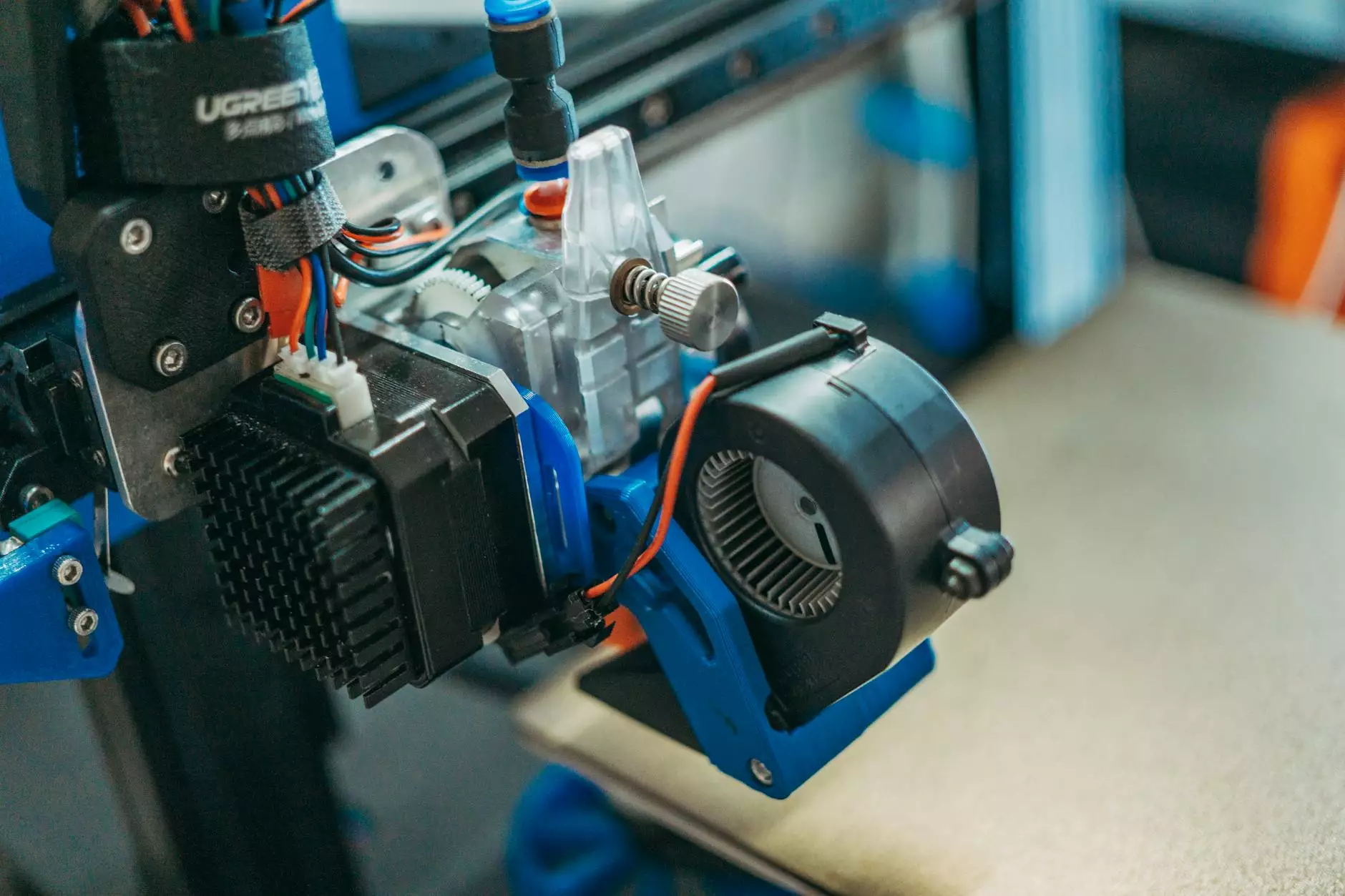

The sophistication of fabric label printers hinges on their core technologies, which dictate print quality, speed, and durability. Major printing technologies used in fabric labeling include:

Heat Transfer Printing

Heat transfer printing employs heat and pressure to transfer ink or foil onto fabric surfaces. It allows for detailed designs and vibrant colors, suitable for small batch or customized labels. DurafastLabel’s heat transfer solutions are optimized for fabric durability and clarity.

Inkjet Printing

High-end industrial inkjet fabric printers use specialized textile inks that bond with fabric fibers, producing high-resolution, photo-quality labels. Inkjet technology offers flexibility in printing complex images, text, and variable data.

Sublimation Printing

Sublimation involves turning dye-based inks into gas under heat, which then permeate the fabric fibers. This technology creates super-durable, vibrant labels suited for polyester and synthetic blends.

Thermal Transfer and RFID Integration

Some fabric label printers incorporate RFID capabilities, revolutionizing inventory management and product tracking, especially in logistics-heavy sectors.

Choosing the Right Fabric Label Printer for Your Business

Not all fabric label printers are suitable for every business. Your choice should depend on various essential factors:

- Production Volume: Determine if your business requires high-speed mass production or small-batch customization.

- Fabric Compatibility: Consider the types of fabrics used in your products – cotton, polyester, blends, or specialty textiles.

- Design Complexity and Detail: For intricate designs with fine details or multiple colors, select printers with high resolution and color accuracy.

- Operational Ease and Maintenance: Look for user-friendly interfaces and reliable support to minimize downtime and training costs.

- Cost Considerations: Balance initial investment with long-term operational and maintenance expenses.

Why DurafastLabel Outranks the Competition in Fabric Label Printing

As a leader in printing services and electronics, DurafastLabel offers unparalleled technology, quality, and support for fabric label printing. Our technological expertise ensures that your business benefits from innovative solutions tailored to meet your unique needs. Here’s why DurafastLabel is the premier choice:

Unmatched Quality and Precision

Our fabric label printers deliver crisp, vibrant, and long-lasting labels, thanks to advanced ink delivery systems and high-resolution printing capabilities. These labels effectively communicate your brand message and withstand rigorous testing environments.

Versatility and Customization

DurafastLabel’s machinery supports a wide range of fabric types, designs, and styles, enabling your business to produce customized labels that align perfectly with your branding strategy.

Superior Durability and Sustainability

Utilizing eco-friendly inks and durable printing methods, our solutions ensure labels resist washing, friction, and environmental stressors without fading or peeling, thereby prolonging the brand’s visual impact.

Exceptional Customer Support and Training

We provide comprehensive onboarding, technical assistance, and ongoing support to maximize your investment’s value, ensuring smooth integration into your manufacturing workflow.

Cost-Effective Solutions

Our fabric label printers are designed for efficiency, reducing waste and minimizing operational costs while maintaining top-tier quality standards.

Applications of Fabric Label Printers in Various Industries

Fabric label printers find extensive use across multiple sectors, each with distinct requirements:

Fashion and Apparel

Enable brands to create eye-catching labels with logos, care symbols, and size information that enhance the brand experience and customer trust.

Sportswear and Outdoor Gear

Produce labels that remain intact during rugged activities and frequent washing, reinforcing the durability of your products.

Home Textiles and Bedding

Generate labels that are soft, fade-resistant, and compliant with safety standards, ensuring quality in products like towels, sheets, and curtains.

Luxury and Custom Textiles

Create high-end labels that exemplify sophistication with fine details, metallic finishes, and premium materials.

Future Trends in Fabric Label Printing Technology

The landscape of fabric label printing continues to evolve rapidly, driven by innovations in digital printing, sustainable materials, and integrated technology. Notable future trends include:

- Eco-friendly and biodegradable inks: Reducing environmental impact while maintaining vibrant color output.

- Smart labels with embedded technology: Incorporating RFID chips, QR codes, and NFC tags to facilitate traceability and augmented reality experiences.

- Automation and AI integration: Streamlining design to print workflows for faster turnaround times and reduced human error.

- On-demand printing and mass customization: Offering consumers personalized products with minimal setup costs.

Final Thoughts: Elevate Your Business with the Best Fabric Label Printing Solutions

Choosing the right fabric label printers is not merely a technological decision; it is a strategic move that impacts branding, quality, and operational efficiency. As the leader in innovative printing solutions, DurafastLabel stands ready to provide you with the most advanced, reliable, and cost-effective fabric label printing systems on the market. Equip your business with the tools to stand out, meet customer demands, and drive growth in an increasingly competitive environment.

By investing in top-tier fabric label printing technology today, you are setting your brand on the path to sustained success, enhanced customer loyalty, and industry leadership. Embrace innovation, quality, and sustainability with DurafastLabel’s comprehensive solutions and take your business to new heights.

https://www.durafastlabel.com/printers-by-technology/fabric-label-printers/